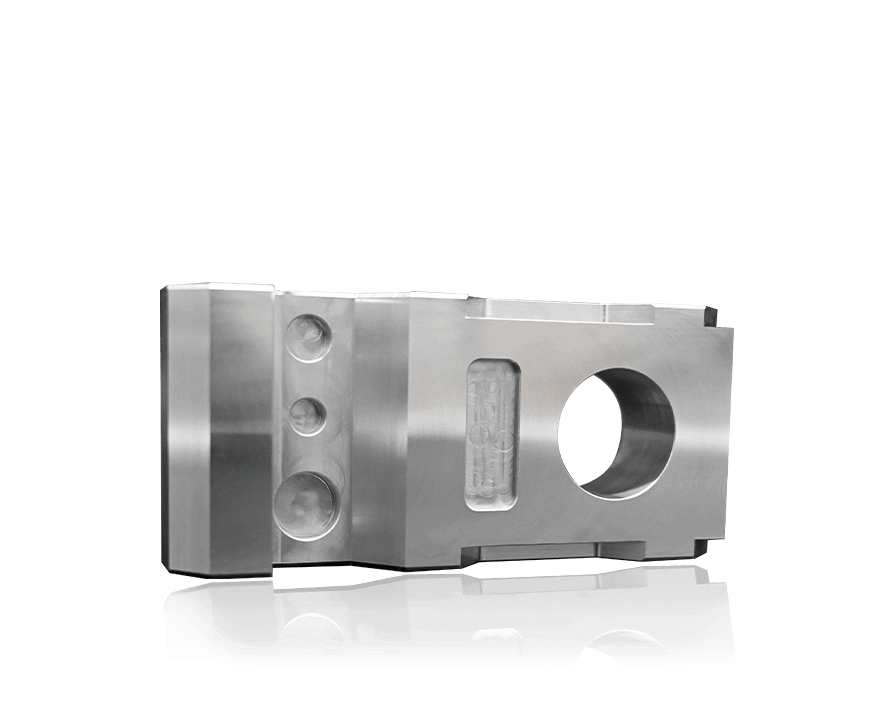

CNC manufacturing: milling & turning

Simply order CNC-milled and turned parts online

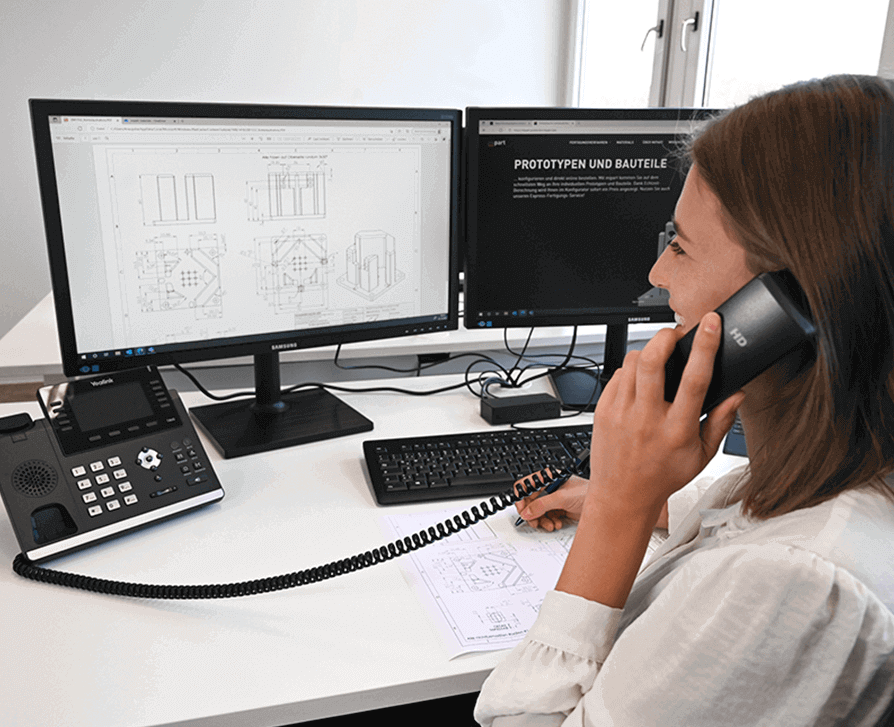

Configure and customise CNC-components without registration - with fair real-time price calculation and guaranteed industrial quality. We also offer 3D printing and sheet metal working - why don’t you have a look?

CNC MANUFACTURING: TURNING

In modern CNC manufacturing of prototypes and component series, turning is one of the most important methods. During turning, the turned part turns around its own axis, while a tool is used to remove chips, as in all other machining processes. The lathe tool moves along the contour that is to be cut on the workpiece to create the desired geometric shape.

In CNC manufacturing, turning is used for rotationally symmetrical components such as axles, shafts and flanges.

YOU HAVE A CAD MODEL?

Upload your CAD model, configure your component and order it online straight away.

Technical data

Materials

Final processing

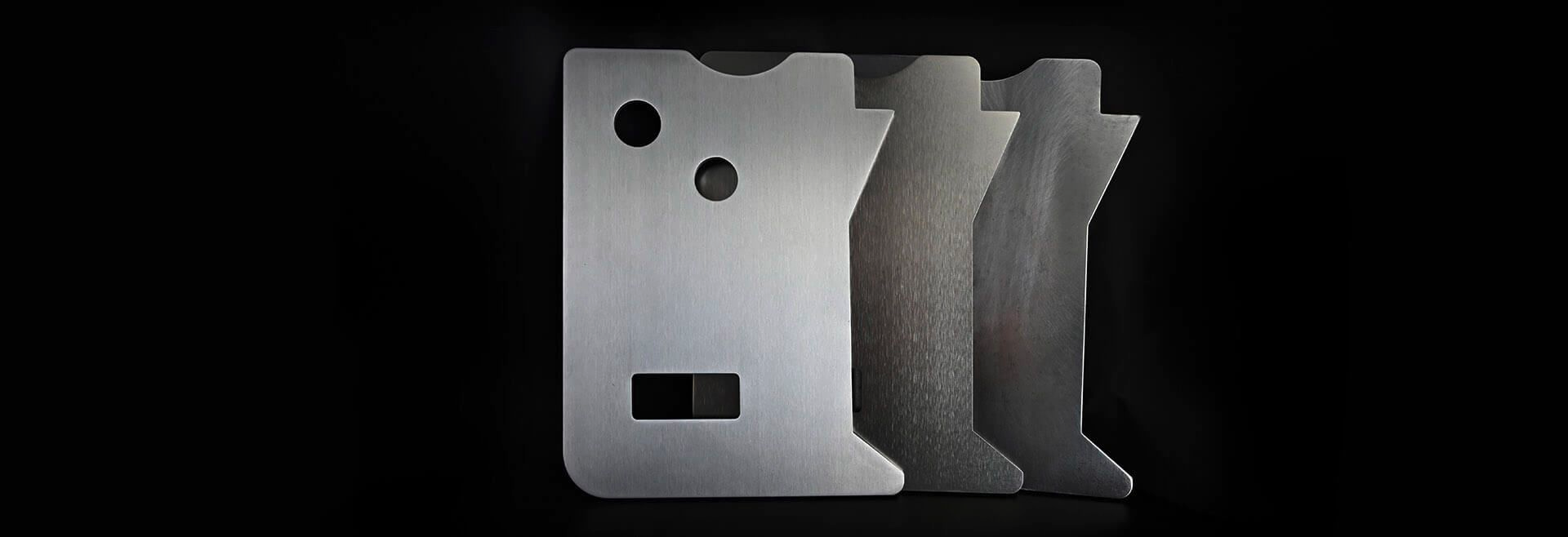

TOP-QUALITY COMPONENTS

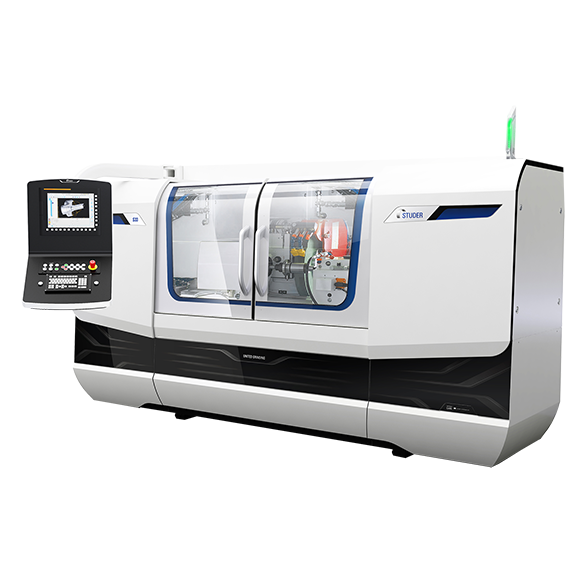

WE RELY COMPETENT AND WELL KNOWN MANUFACTURING PARTNERS

To manufacture the best prototypes and components, our manufacturing partners are using the state-of-the-art machines of premium manufacturers such as DMG MORI, Stama or Kern Microtechnik. Digital and automated processes with pallet changing and robot systems contribute to excellent results in CNC manufacturing.

ADVANTAGES AND APPLICATIONS

YOUR PARTNER FOR MACHINING PROCESSES

On-demand-manufacturing with mipart means full service from one source. Modern CNC manufacturing methods allow us to efficiently produce turned and milled parts in practically any geometric shape. Choose us and benefit from top-quality components with high surface quality, tight tolerances and high mechanical strength. We have experience with a wide variety of customers and applications from numerous different fields: From hobbyists and car tuners to large machine and plant building companies, to aerospace and medical technology. Whether you’re looking for customized prototypes or series - we will handle all of your CNC manufacturing jobs, so you only need a single point of contact.

AUTOMATIC FEATURE DETECTION

THREAD

M2 to M16 | G ¼ to G ½ Withworth

Our software automatically detects holes that are suitable for a thread. If you make the selections accordingly, the costs for thread cutting are included directly in the calculation.

FITS

2 H7 to 16 H7

Our feature detection also allows you to select fits. At the moment we only offer standard fits. But we will shortly expand our available options.

INDUSTRY STANDARD

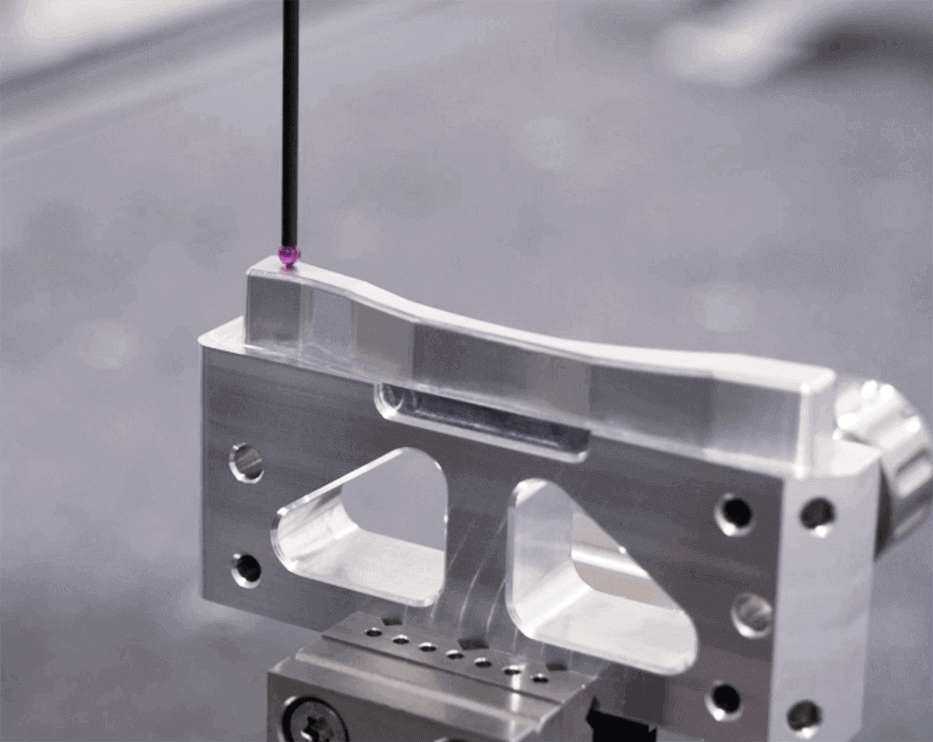

General tolerances according to ISO 2768-1 medium and fine

By using a Zeiss measuring machine, we can measure any tolerance and, on request, prove it with an initial sample test report.

SPECIAL REQUESTS

We would be glad to submit a customized quotation for engravings, additional heat treatment and surface finishes such as anodizing or glass bead blasting.

You require calculation and manufacturing of components larger than 650 x 650 x 400 mm? No problem, simply contact us by e-mail to info@mipart.com.

EXCERPT OF OUR MACHINE OUTFIT

YOU HAVE A CAD MODEL?

UPLOAD IT TO THE CONFIGURATOR NOW

CNC manufacturing goes digital! Our online configurator will get you your customized component in just a few steps. Simply upload a CAD model, configure your component as desired and order it online straight way. With real-time price calculation! There is no quicker and simpler way.

DISCOVER OUR CUSTOMER EXAMPLES