3D Printing

Your 3D printing online service for additive manufacturing of prototypes and component series

Thanks to its special features and advantages, additive manufacturing has become firmly established alongside conventional manufacturing processes. 3D printing will give you maximum design freedom and will allow you to make your ideas a reality quickly and at affordable prices. 3D printing is ideal for rapid prototyping, product development, small batches and service work - simply select the right process and materials for your application and quality requirements from a long list. You need advice to find the right material and process for you? We have tips for you on this page!

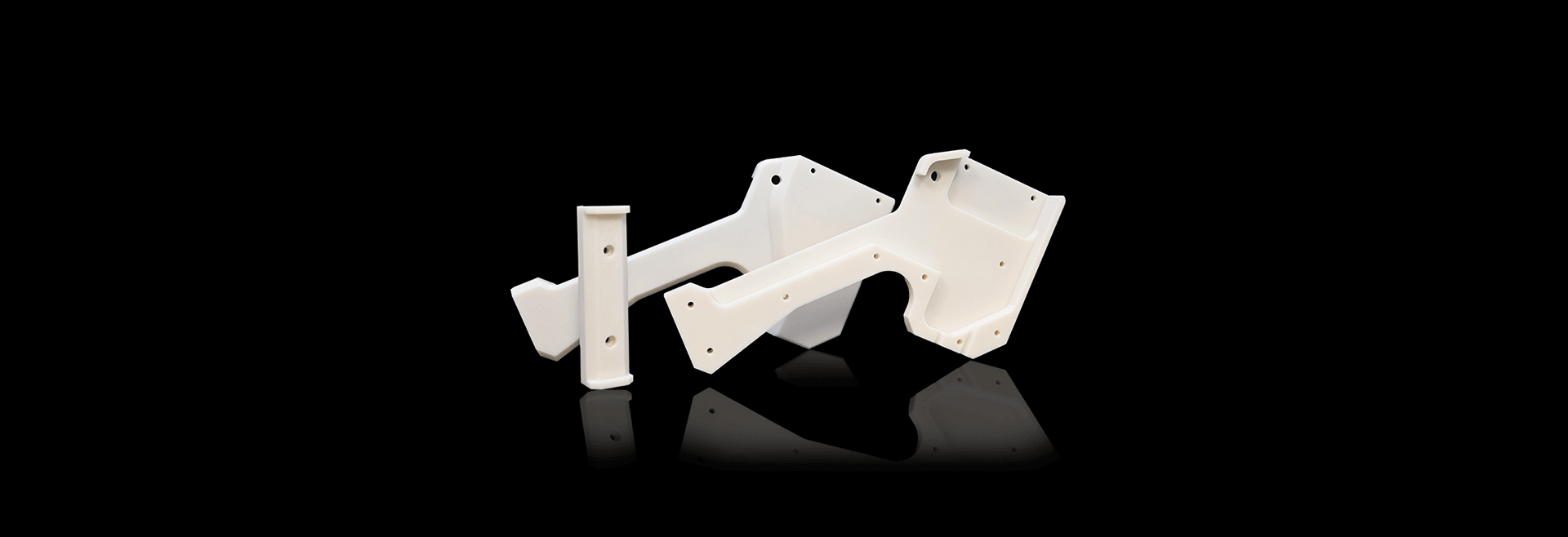

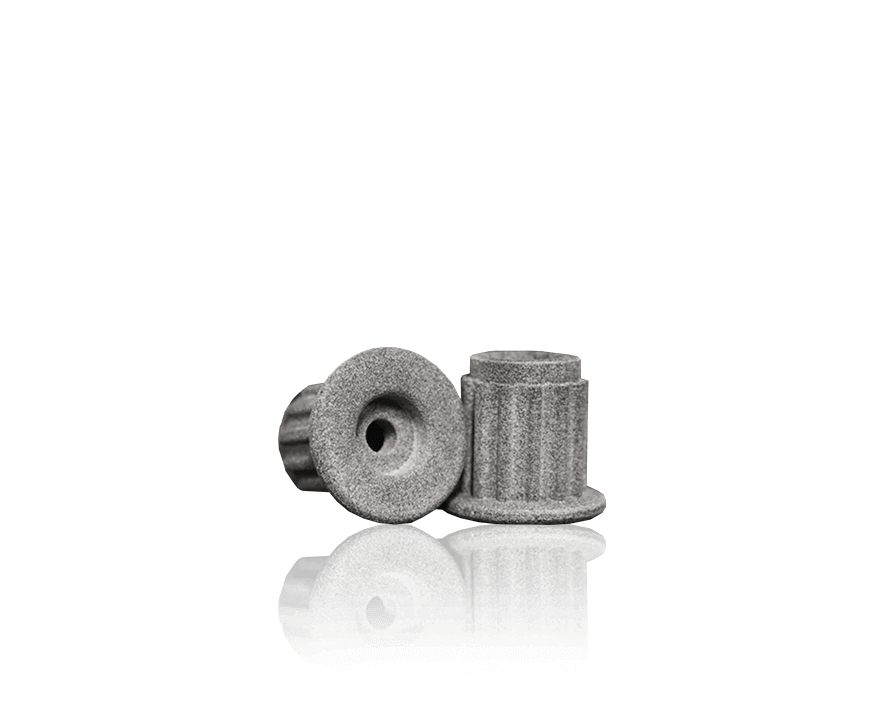

3D PRINTING with FDM

FDM is the abbreviation of Fused Deposition Modeling This 3D printing process will impress you with its excellent value for money and is particularly suitable for applications that do not require completely perfect surfaces and geometric details. A wide range of available materials offers plenty of advantages, e.g. materials with high strength and rigidity. This makes Fused Deposition Modeling ideal for functional prototypes or concept studies, but also for components in device and tool making and for manufacturing operating equipment.

In the FDM method, the filament is unwound from a coil and inserted into a heatable extruder. There it is heated, melted and vertically applied to a build plate under pressure, layer by layer, until the desired object is created.

YOU HAVE A CAD MODEL?

Upload your CAD model, configure your component and order it online straight away.

Technical data

Materials

Final processing

SELECTING THE ADDITIVE MANUFACTURING METHOD

RECOMMENDATION OF OUR 3D PRINTING EXPERTS

Nowadays there are numerous different additive manufacturing methods and suitable materials. To produce a 3D printed component that meets all requirements and matches your vision, it is best to select a suitable method and material. Take the following factors into account when making your decision:

3D PRINTING ONLINE SERVICE

HOW YOUR COMPONENT IS CREATED

We are glad to offer a diverse set of machine capabilities and our experiences in 3D printing. Here you can learn which services are included and how we create your component with our 3D printing service.

ADVANTAGES of 3D PRINTING OVER CONVENTIONAL MANUFACTURING PROCESSES

RAPID PROTOTYPING

Quick delivery of installation-ready components

Receive immediately usable components instead of semi-finished goods. As printing jobs can be started immediately, production takes very little time.

SERIAL PRODUCTION

If we can do one, we can do more

Our multi jet fusion process is a good alternative to conventional injection molding for small or medium-sized series.

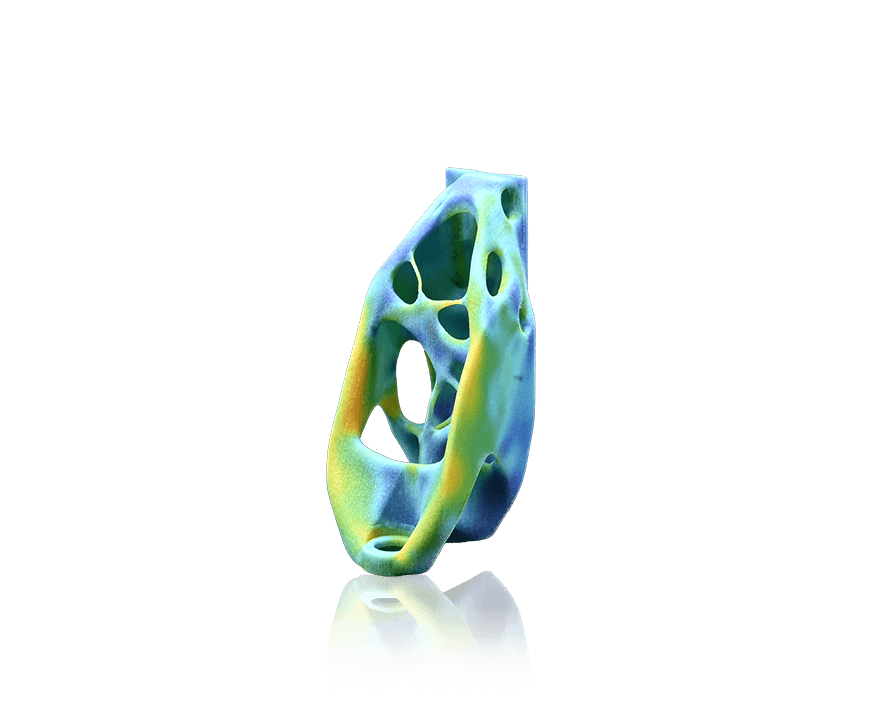

DESIGN FREEDOM

Light-weight construction

Internal honeycomb, sandwich and lattice structures or hollow spaces reduce weight and material use without losing rigidity. We would be glad to advise you on your options for optimizing topology.

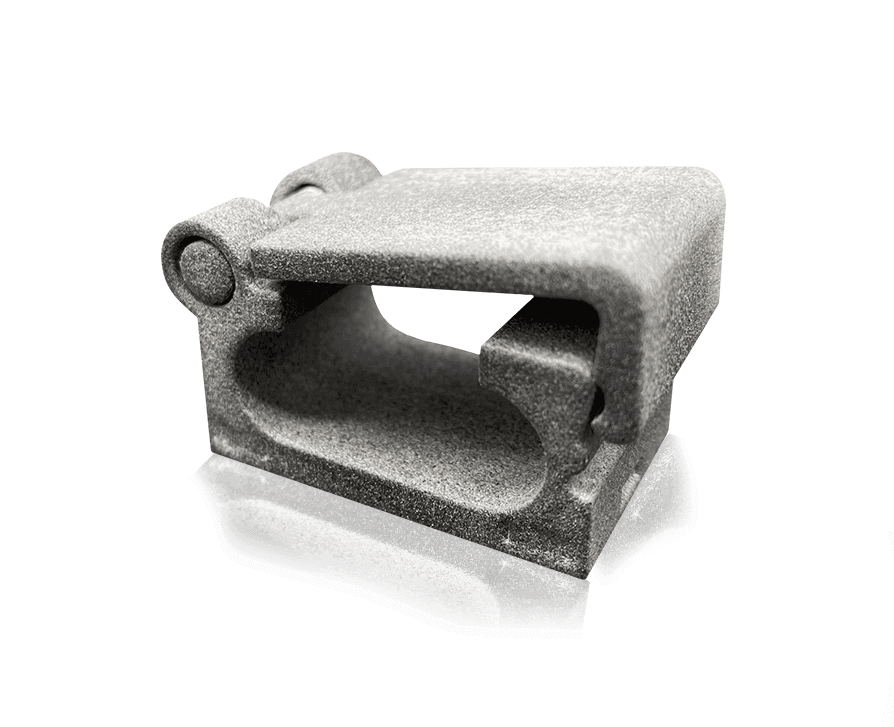

FUNCTION INTEGRATION

Entire assembly groups turn into a single component

3D printing permits production of functional assembly groups in one printing job. This saves time and process costs. Why keep assembling individual components?

EXCERPT OF OUR MACHINE OUTFIT

YOU HAVE A CAD MODEL?

UPLOAD IT TO THE CONFIGURATOR NOW

3D printing goes digital! Our online configurator will get you your customized component in just a few steps. Simply upload a CAD model, configure your component as desired and order it online straight way. With real-time price calculation! There is no quicker and simpler way.

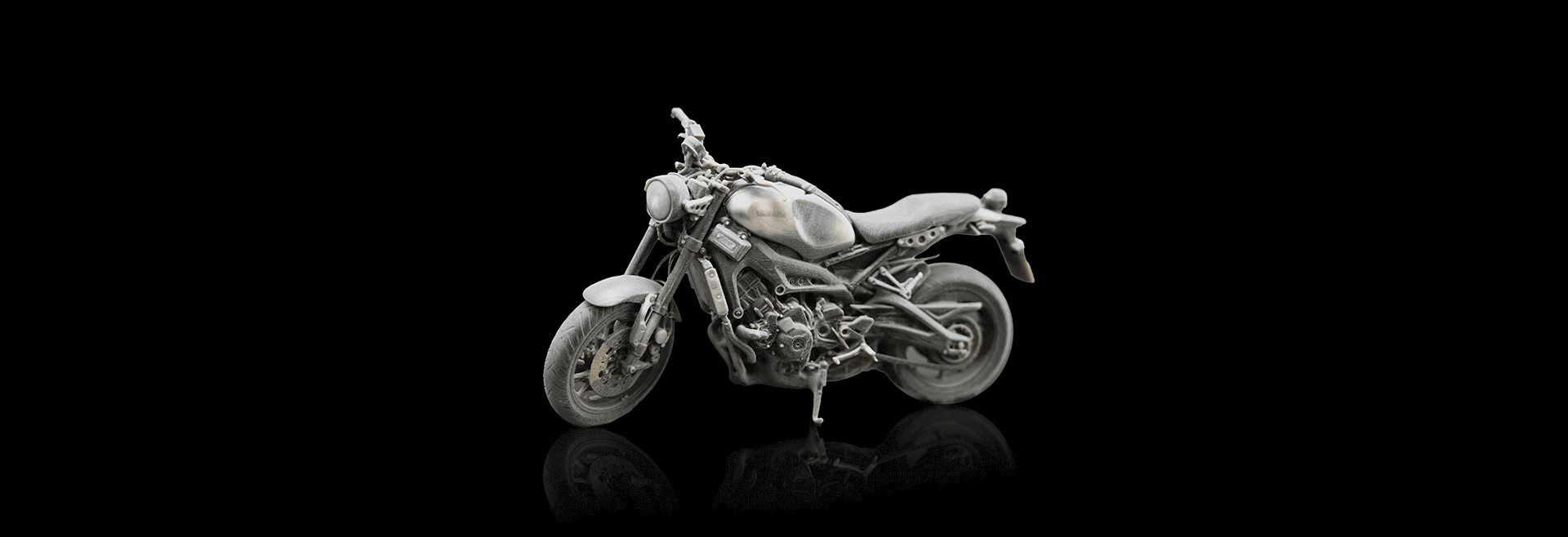

DISCOVER OUR CUSTOMER EXAMPLES